Automatic visual pipe inspection system jointly developed with FUJIFILM Engineering Co., Ltd.

By applying the component technology of FUJIFILM Engineering to meet the visual criteria (flaws, impressions, scratches, etc.) demanded by customers, we succeeded in achieving unparalleled detection capabilities.

To meet the quality level demanded by our customers, we developed an inspection system jointly with FUJIFILM Engineering.

The system enables quantifying the depth and size of flaws and impressions in the exterior and judging whether they are acceptable.

By introducing this inspection system, we were able to eliminate inconsistencies arising from human judgment. We are working to eliminate the causes of defects by investigating the causal elements and feeding information back to the production process.

The inspection system also produces evidence that we can provide to customers to enhance the reliability of our products.

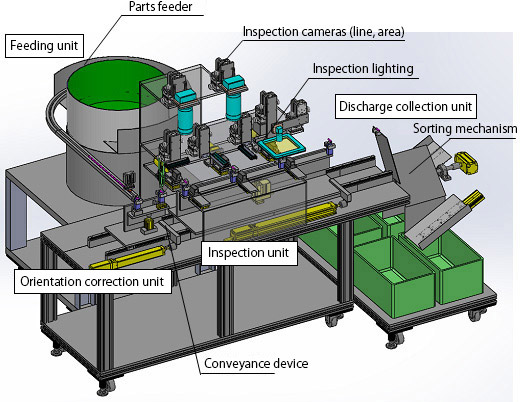

This is an illustration of the system put to practical application.

The exterior of each part is photographed with a CCD camera, and the captured image is processed to instantly make an inspection judgment and screen the part accordingly.

We manufacture many critical parts such as automotive parts, where even small flaws or irregularities can cause a serious accident.

For the stable supply of parts, advanced production technologies as well as reliable quality inspection are essential.

By leveraging a special optical design and sophisticated image processing technologies, we have developed and put to practical application a system that can automatically and reliably inspect and screen defects such as minute flaws, irregularities, and blemishes on the surface of processed metal pipes—a task that used to be performed through visual inspection with the human eye.

This has reduced inspection costs considerably and acquired the trust of customers.